Foyilo yamkuwaIli ndi mpweya wochepa pamwamba ndipo imatha kulumikizidwa ndi zinthu zosiyanasiyana monga chitsulo, zinthu zotetezera kutentha. Ndipo zinthu zamkuwa zimagwiritsidwa ntchito makamaka poteteza maginito ndi maginito. Kuti ipange zinthu zamkuwa zoyendetsedwa ndi maginito pamwamba pa zinthuzo komanso kuphatikiza ndi zinthu zachitsulo, ipereka chitetezo chabwino kwambiri komanso maginito. Ikhoza kugawidwa m'magulu awa: zinthu zamkuwa zodzimatira zokha, zinthu zamkuwa za mbali imodzi, zinthu zamkuwa za mbali ziwiri ndi zina zotero.

Mu ndime iyi, ngati mukufuna kudziwa zambiri za zojambula zamkuwa zomwe zimagwiritsidwa ntchito popanga ma PCB, chonde onani ndikuwerenga zomwe zili pansipa kuti mudziwe zambiri zaukadaulo.

Kodi zinthu zomwe zimapangidwa ndi foil yamkuwa mu kupanga PCB ndi ziti?

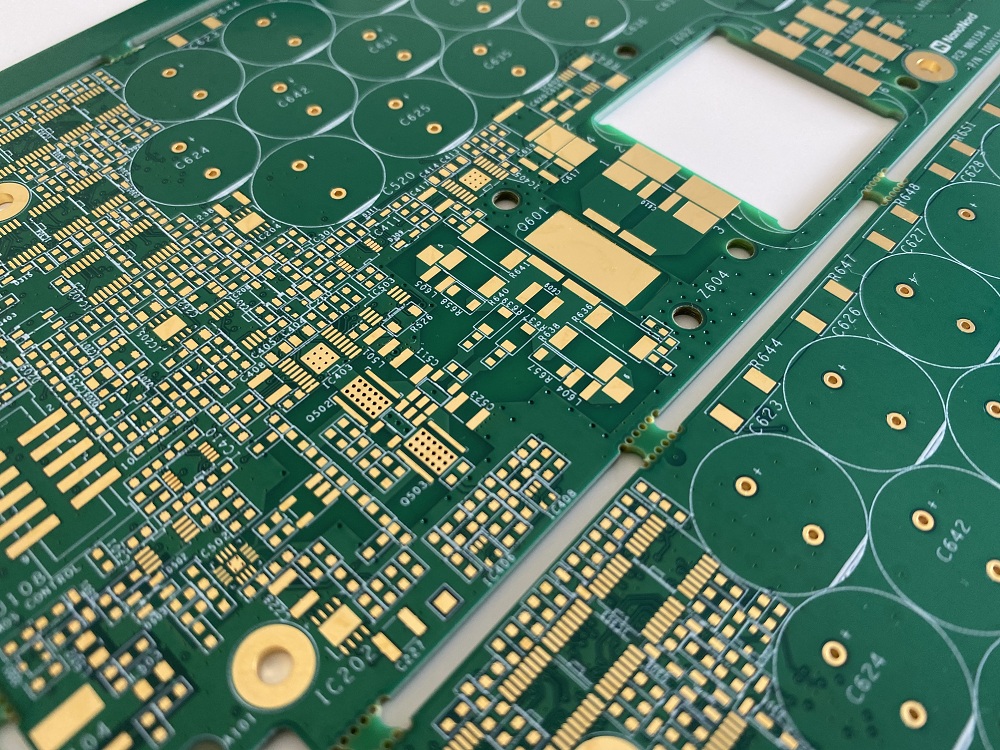

Zojambula zamkuwa za PCBndi makulidwe oyamba a mkuwa omwe amagwiritsidwa ntchito pa zigawo zakunja ndi zamkati za bolodi la PCB la multilayer. Kulemera kwa mkuwa kumatanthauzidwa ngati kulemera (mu ma ounces) kwa mkuwa komwe kulipo mu 1 sikweya mita imodzi ya malo. Gawoli likuwonetsa makulidwe onse a mkuwa pa wosanjikiza. MADPCB imagwiritsa ntchito zolemera zotsatirazi za mkuwa popanga PCB (pre-plate). Zolemera zomwe zimayesedwa mu oz/ft2. Kulemera koyenera kwa mkuwa kumatha kusankhidwa kuti kugwirizane ndi zofunikira pa kapangidwe.

· Pakupanga ma PCB, ma foil amkuwa amakhala m'ma rolls, omwe ndi amagetsi okhala ndi chiyero cha 99.7%, ndi makulidwe a 1/3oz/ft2 (12μm kapena 0.47mil) – 2oz/ft2 (70μm kapena 2.8mil).

· Foil ya mkuwa ili ndi mpweya wochepa pamwamba ndipo opanga laminate amatha kulumikizidwa kale ku zipangizo zosiyanasiyana, monga chitsulo chapakati, polyimide, FR-4, PTFE ndi ceramic, kuti apange laminate yokhala ndi mkuwa.

· Ikhozanso kulowetsedwa mu bolodi la multilayer ngati foil yamkuwa musanayikanikize.

· Pakupanga ma PCB achikhalidwe, makulidwe omaliza a mkuwa pa zigawo zamkati amatsalira pa pepala loyambirira la mkuwa; Pa zigawo zakunja timayika mkuwa wowonjezera wa 18-30μm pa njanji panthawi yopangira ma panel plating.

· Mkuwa wa zigawo zakunja za matabwa ambiri uli ngati pepala la mkuwa ndipo umakanizidwa pamodzi ndi ma prepregs kapena cores. Kuti ugwiritsidwe ntchito ndi ma microvias mu HDI PCB, pepala la mkuwa limakhala mwachindunji pa RCC (mkuwa wophimbidwa ndi resin).

N’chifukwa chiyani zojambulazo zamkuwa zimafunika popanga PCB?

Chikwama cha mkuwa chamagetsi (choyera kuposa 99.7%, makulidwe 5um-105um) ndi chimodzi mwazinthu zoyambira zamakampani amagetsi. Kukula mwachangu kwa makampani opanga chidziwitso chamagetsi, kugwiritsa ntchito chikwama chamkuwa chamagetsi kukukula, zinthuzi zimagwiritsidwa ntchito kwambiri mu ma calculator amafakitale, zida zolumikizirana, zida za QA, mabatire a lithiamu-ion, ma TV wamba, zojambulira makanema, osewera ma CD, zokopera, foni, mpweya wozizira, zamagetsi zamagalimoto, zotonthoza zamasewera.

Zojambula zamkuwa zamakampaniZingagawidwe m'magulu awiri: cholembera cha mkuwa chopindidwa (cholembera cha mkuwa cha RA) ndi cholembera cha mkuwa cha point (cholembera cha mkuwa cha ED), momwe cholembera cha mkuwa chopindidwa chili ndi ductility yabwino komanso makhalidwe ena, ndi njira yoyambirira yofewa yogwiritsira ntchito cholembera cha mkuwa, pomwe cholembera cha mkuwa cha electrolytic ndi mtengo wotsika wopanga cholembera cha mkuwa. Popeza cholembera cha mkuwa chopindidwa ndi chinthu chofunikira kwambiri pa bolodi lofewa, momwemonso makhalidwe a cholembera cha mkuwa chopindidwa ndi kusintha kwa mitengo pamakampani a bolodi lofewa zimakhudza kwambiri.

Kodi malamulo oyambira a kapangidwe ka zojambula zamkuwa mu PCB ndi ati?

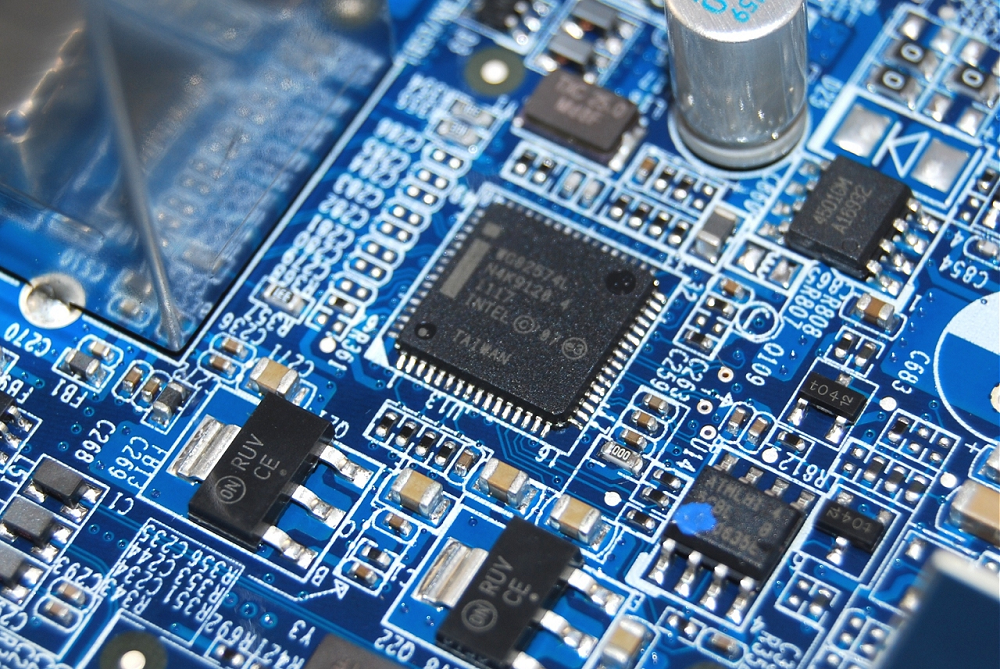

Kodi mukudziwa kuti ma circuit board osindikizidwa ndi ofala kwambiri m'gulu la zamagetsi? Ndikutsimikiza kuti pali imodzi mu chipangizo chamagetsi chomwe mukugwiritsa ntchito pakali pano. Komabe, kugwiritsa ntchito zida zamagetsi izi popanda kumvetsetsa ukadaulo wawo komanso njira yopangira ndi njira yodziwika bwino. Anthu amagwiritsa ntchito zida zamagetsi ola lililonse koma sadziwa momwe zimagwirira ntchito. Ndiye nazi zina mwa zigawo zazikulu za PCB zomwe zatchulidwa kuti zimamvetsetsa mwachangu momwe ma circuit board osindikizidwa amagwirira ntchito.

· Bolodi losindikizidwa la dera ndi matabwa apulasitiki osavuta okhala ndi galasi. Chojambula cha mkuwa chimagwiritsidwa ntchito potsata njira ndipo chimalola kuyenda kwa ma charge ndi zizindikiro mkati mwa chipangizocho. Ma traces a mkuwa ndi njira yoperekera mphamvu ku zigawo zosiyanasiyana za chipangizo chamagetsi. M'malo mwa mawaya, ma traces a mkuwa amatsogolera kuyenda kwa ma charge mu ma PCB.

· Ma PCB amatha kukhala ndi gawo limodzi komanso magawo awiri. PCB imodzi yokhala ndi magawo ndi yosavuta. Ali ndi foil ya mkuwa mbali imodzi ndipo mbali inayo ndi malo a zigawo zina. Pa PCB yokhala ndi magawo awiri, mbali zonse ziwiri zimasungidwa kuti zigwiritsidwe ntchito popanga foil ya mkuwa. Ma PCB okhala ndi magawo awiri ndi ovuta omwe ali ndi zizindikiro zovuta zoyendetsera magetsi. Palibe foil ya mkuwa yomwe ingadutsenane. Ma PCB awa amafunika pazida zamagetsi zolemera.

· Palinso zigawo ziwiri za zosungunula ndi silkscreen pa PCB yamkuwa. Chigoba chosungunula chimagwiritsidwa ntchito kusiyanitsa mtundu wa PCB. Pali mitundu yambiri ya ma PCB yomwe ilipo monga wobiriwira, wofiirira, wofiira, ndi zina zotero. Chigoba chosungunula chimafotokozanso mkuwa kuchokera ku zitsulo zina kuti timvetse zovuta za kulumikizana. Ngakhale silkscreen ndi gawo la zolemba za PCB, zilembo ndi manambala osiyanasiyana amalembedwa pa silkscreen kwa wogwiritsa ntchito komanso injiniya.

Kodi mungasankhe bwanji zinthu zoyenera zopangira zojambulazo zamkuwa mu PCB?

Monga tanenera kale, muyenera kuwona njira yodziwira njira yopangira bolodi losindikizidwa. Kupanga kwa ma board awa kuli ndi zigawo zosiyanasiyana. Tiyeni timvetse izi ndi ndondomekoyi:

Zinthu zomangira pansi:

Maziko a pansi pa bolodi la pulasitiki lomwe limayikidwa ndi galasi ndi gawo lapansi. Gawo lapansi ndi kapangidwe ka dielectric ka pepala lomwe nthawi zambiri limapangidwa ndi ma epoxy resins ndi pepala lagalasi. Gawo lapansi limapangidwa mwanjira yoti likwaniritse zofunikira mwachitsanzo kutentha kwa kusintha (TG).

Kupaka utoto:

Monga momwe dzinalo likusonyezera, lamination ndi njira yopezera zinthu zofunika monga kutentha, mphamvu yochepetsera, ndi kutentha kwa transition (TG). Lamination imachitika pansi pa kupanikizika kwakukulu. Lamination ndi substrate pamodzi zimagwira ntchito yofunika kwambiri pakuyenda kwa magetsi mu PCB.

Nthawi yotumizira: Juni-02-2022