Popeza mkuwa ndi wokongola kwambiri m'zinthu zosiyanasiyana zamafakitale, umaonedwa ngati chinthu chogwiritsidwa ntchito m'njira zosiyanasiyana.

Ma foil a mkuwa amapangidwa pogwiritsa ntchito njira zapadera kwambiri zopangira mkati mwa fakitole ya foil yomwe imaphatikizapo kupukuta kotentha komanso kozizira.

Pamodzi ndi aluminiyamu, mkuwa umagwiritsidwa ntchito kwambiri m'mafakitale ngati chinthu chogwiritsidwa ntchito mosiyanasiyana pakati pa zitsulo zopanda chitsulo. Makamaka m'zaka zaposachedwa, kufunikira kwa zojambulazo zamkuwa kwakhala kukuchulukirachulukira pazinthu zamagetsi kuphatikizapo mafoni am'manja, makamera a digito, ndi zida za IT.

Kupanga zojambulazo

Ma foil opyapyala amkuwa amapangidwa ndi electrodeposition kapena rolling. Pa electrodeposition, mkuwa wapamwamba uyenera kusungunuka mu asidi kuti upange electrolyte yamkuwa. Yankho la electrolyte ili limapopedwa mu ma ng'oma ozungulira omwe amamizidwa pang'ono omwe amayendetsedwa ndi magetsi. Pa ma ng'oma awa, filimu yopyapyala ya mkuwa imayikidwa ndi electrodeposition. Njirayi imadziwikanso kuti plating.

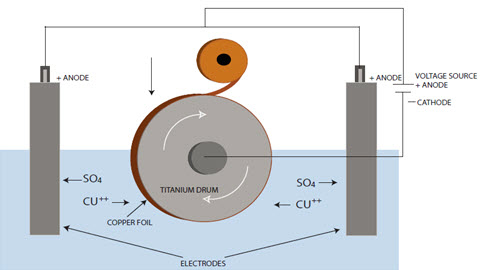

Mu njira yopangira mkuwa yokhala ndi electrode, foil yamkuwa imayikidwa pa ng'oma yozungulira ya titaniyamu kuchokera ku yankho la mkuwa komwe imalumikizidwa ku gwero la DC voltage. Cathode imalumikizidwa ku ng'oma ndipo anode imamizidwa mu yankho la electrolyte yamkuwa. Pamene mphamvu yamagetsi ikugwiritsidwa ntchito, mkuwa umayikidwa pa ng'oma pamene ukuzungulira pang'onopang'ono kwambiri. Pamwamba pa mkuwa kumbali ya ng'oma ndi yosalala pomwe mbali inayo ndi yolimba. Liwiro la ng'oma likakhala lochepa, mkuwa umakhala wokhuthala kwambiri ndipo mosemphanitsa. Mkuwa umakokedwa ndikusonkhanitsidwa pamwamba pa cathode ya ng'oma ya titaniyamu. Mbali ya matte ndi ng'oma ya foil yamkuwa imadutsa munjira zosiyanasiyana zochizira kuti mkuwa ukhale woyenera kupanga PCB. Mankhwalawa amawonjezera kumatirira pakati pa mkuwa ndi dielectric interlayer panthawi ya copper clad lamination. Ubwino wina wa mankhwalawa ndikuchita ngati mankhwala oletsa kuwononga mwa kuchepetsa kukhuthala kwa mkuwa.

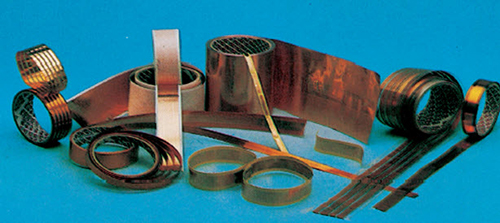

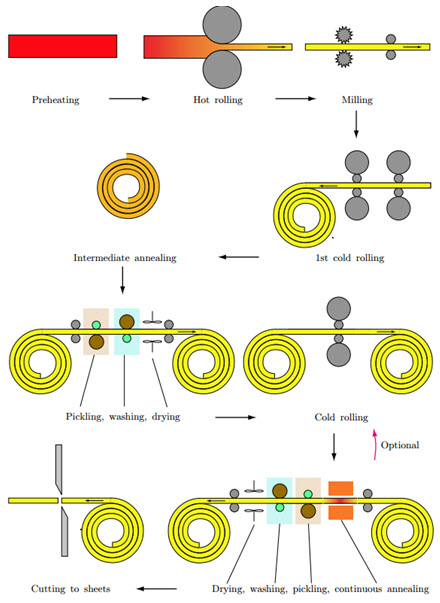

Chithunzi 1:Njira Yopangira Mkuwa Yosungidwa ndi Magetsi Chithunzi 2 chikuwonetsa njira zopangira zinthu zamkuwa zokulungidwa. Zipangizo zokulungidwa zimagawidwa m'mitundu itatu; yomwe ndi, mphero zotentha, mphero zozizira, ndi mphero za zojambulazo.

Ma coil a ma foil opyapyala amapangidwa ndipo amakonzedwa ndi mankhwala ndi makina mpaka atapangidwa kukhala mawonekedwe awo omaliza. Chidule cha njira yozungulira ma foil a mkuwa chaperekedwa mu Chithunzi 2. Bulu la mkuwa wopangidwa (pafupifupi miyeso: 5mx1mx130mm) limatenthedwa mpaka 750°C. Kenako, limatenthedwa mozungulira pang'onopang'ono m'magawo angapo mpaka 1/10 ya makulidwe ake oyambirira. Kuzizira koyamba kusanayambe, mamba omwe amachokera ku kutentha amachotsedwa ndi kugaya. Mu njira yozizira yozungulira makulidwe amachepetsedwa kufika pafupifupi 4 mm ndipo mapepala amapangidwa kukhala ma coil. Njirayi imayendetsedwa mwanjira yoti zinthuzo zimatalika ndipo sizisintha m'lifupi mwake. Popeza mapepalawo sangapangidwenso kwambiri mu mkhalidwe uwu (zinthuzo zagwira ntchito molimbika kwambiri), amatenthedwa ndipo amatenthedwa kufika pafupifupi 550°C.

Nthawi yotumizira: Ogasiti-13-2021