Pokhala ndi chidwi chachikulu muzinthu zambiri zamakampani, mkuwa umawoneka ngati chinthu chosinthika kwambiri.

Zojambula za mkuwa zimapangidwa ndi njira zopangira zopangira mkati mwa mphero zomwe zimaphatikizapo kutentha ndi kuzizira.

Pamodzi ndi aluminiyumu, mkuwa umagwiritsidwa ntchito kwambiri m'mafakitale ngati chinthu chosunthika kwambiri pakati pa zinthu zopanda chitsulo. Makamaka m'zaka zaposachedwa, kufunikira kwa zojambula zamkuwa kwakhala kukukulirakulira pazinthu zamagetsi kuphatikiza mafoni am'manja, makamera a digito, ndi zida za IT.

Kupanga foil

Zojambula zamkuwa zopyapyala zimapangidwa ndi electrodeposition kapena rolling. Pakuti electrodeposition mkulu kalasi mkuwa ayenera kusungunuka mu asidi kupanga electrolyte yamkuwa. Njira ya electrolyte iyi imaponyedwa mu ng'oma zomizidwa pang'ono, zozungulira zomwe zimayikidwa pamagetsi. Pa ng'oma izi filimu woonda wamkuwa ndi electrodeposited. Njirayi imatchedwanso plating.

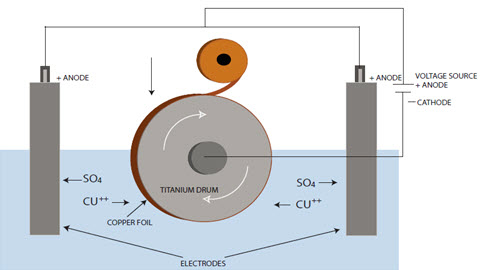

Popanga ma electrodeposited mkuwa, zojambulazo zimayikidwa pa ng'oma yozungulira ya titaniyamu kuchokera munjira yamkuwa pomwe imalumikizidwa ndi gwero lamagetsi la DC. Cathode imamangiriridwa ku ng'oma ndipo anode imamizidwa mumkuwa wa electrolyte. Malo amagetsi akagwiritsidwa ntchito, mkuwa umayikidwa pa ng'oma pamene imayenda pang'onopang'ono kwambiri. Pamwamba pa mkuwa pa mbali ya ng'oma ndi yosalala pamene mbali inayo ndi yovuta. Pamene ng'oma imathamanga pang'onopang'ono, mkuwa umakhala wokhuthala komanso mosiyana. Mkuwa umakopeka ndikuunjikira pa cathode pamwamba pa ng'oma ya titaniyamu. Mbali ya matte ndi ng'oma ya zojambulazo zamkuwa zimadutsa njira zosiyanasiyana zothandizira kuti mkuwa ukhale woyenera kupanga PCB. Mankhwalawa amathandizira kumamatira pakati pa mkuwa ndi dielectric interlayer panthawi yachitsulo chamkuwa. Ubwino wina wamankhwalawa ndikuchita ngati anti-tarnish agents pochepetsa oxidation yamkuwa.

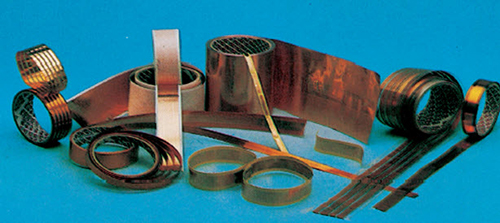

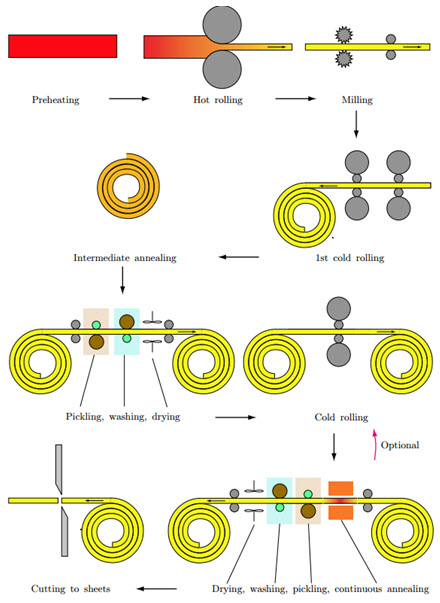

Chithunzi 1:Electrodeposited Copper Manufacturing Process Chithunzi 2 chikuwonetsa njira zopangira zinthu zamkuwa zokulungidwa. Zida zogudubuza zimagawidwa m'mitundu itatu; monga mphero zotentha, mphero zozizira, ndi mphero.

Zojambula zazitsulo zopyapyala zimapangidwira ndipo zimathandizidwa ndi mankhwala ndi makina mpaka zitapangidwa kukhala mawonekedwe awo omaliza. Chithunzi cha 2. Chidutswa cha mkuwa wonyezimira (pafupifupi miyeso: 5mx1mx130mm) chimatenthedwa mpaka 750°C. Kenako, imakhala yotentha yokulungidwa mosinthika pamasitepe angapo mpaka 1/10 ya makulidwe ake oyamba. Asanayambe kuzizira koyamba, mamba omwe amachokera ku kutentha amachotsedwa ndi mphero. M'nyengo yozizira, makulidwewo amachepetsedwa kufika pafupifupi 4 mm ndipo mapepala amapangidwa kuti azizungulira. Njirayi imayendetsedwa m'njira yoti zinthuzo zimangotalika ndipo sizisintha m'lifupi mwake. Monga mapepala sangathe kupangidwanso mopitilira muyeso (zinthu zakhala zikugwira ntchito molimbika kwambiri) amapatsidwa chithandizo cha kutentha ndipo amatenthedwa pafupifupi 550 ° C.

Nthawi yotumiza: Aug-13-2021