Makampani opanga zinthu za PCB agwiritsa ntchito nthawi yambiri popanga zinthu zomwe zimapangitsa kuti chizindikiro chitayike kwambiri. Pa mapangidwe othamanga kwambiri komanso ma frequency apamwamba, kutayika kudzachepetsa mtunda wofalikira kwa chizindikiro ndikusokoneza ma signal, ndipo kudzapanga kusiyana kwa impedance komwe kungawonekere mu muyeso wa TDR. Pamene tikupanga bolodi lililonse losindikizidwa ndikupanga ma circuit omwe amagwira ntchito pama frequency apamwamba, zingakhale zovuta kusankha mkuwa wosalala kwambiri pamapangidwe onse omwe mumapanga.

Ngakhale kuti n’zoona kuti kuuma kwa mkuwa kumapangitsa kuti pakhale kupotoka ndi kutayika kwa impedance, kodi foil yanu ya mkuwa iyenera kukhala yosalala bwanji? Kodi pali njira zosavuta zomwe mungagwiritse ntchito kuti muthane ndi kutayika popanda kusankha mkuwa wosalala kwambiri pa kapangidwe kalikonse? Tiona mfundo izi m’nkhaniyi, komanso zomwe mungayang’ane ngati muyamba kugula zinthu za PCB stackup.

Mitundu yaZojambulazo za Mkuwa za PCB

Kawirikawiri tikamalankhula za mkuwa pa zipangizo za PCB, sitilankhula za mtundu weniweni wa mkuwa, timangolankhula za kuuma kwake. Njira zosiyanasiyana zoyika mkuwa zimapanga mafilimu okhala ndi mitundu yosiyanasiyana ya kuuma, zomwe zitha kudziwika bwino pachithunzi cha scanning electron microscope (SEM). Ngati mukugwira ntchito pama frequency apamwamba (nthawi zambiri 5 GHz WiFi kapena kupitirira apo) kapena pa liwiro lalikulu, ndiye kuti samalani ndi mtundu wa mkuwa womwe watchulidwa mu datasheet yanu.

Komanso, onetsetsani kuti mwamvetsa tanthauzo la ma values a Drk mu deta. Onerani zokambirana za podcast izi ndi John Coonrod wochokera ku Rogers kuti mudziwe zambiri za ma specifications a Drk. Poganizira zimenezi, tiyeni tiwone mitundu yosiyanasiyana ya PCB copper foil.

Yosungidwa ndi ma electrode

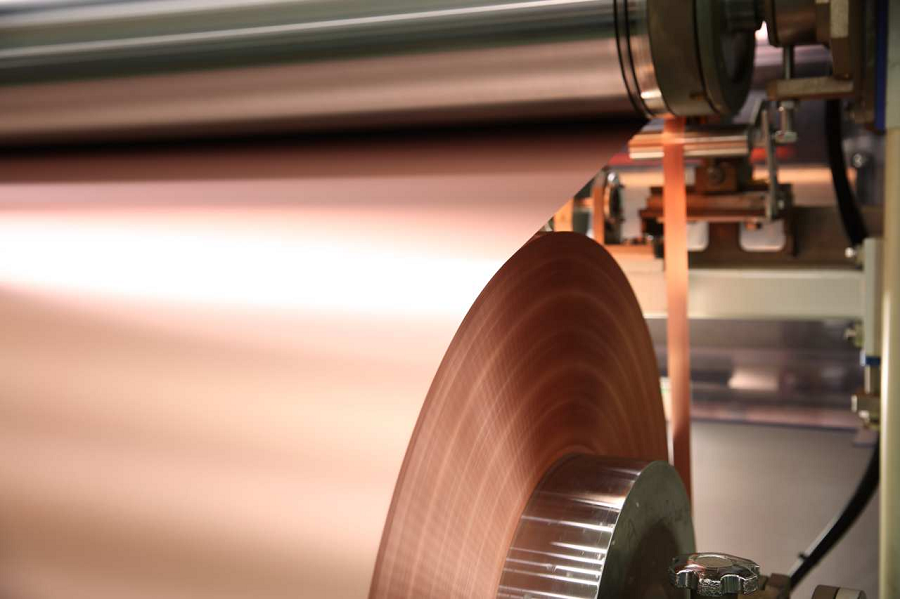

Munjira imeneyi, ng'oma imazunguliridwa kudzera mu yankho la electrolytic, ndipo njira yosinthira ma electrode imagwiritsidwa ntchito "kukulitsa" zojambulazo zamkuwa pa ng'oma. Pamene ng'oma ikuzungulira, filimu yamkuwa yomwe imachokera imakulungidwa pang'onopang'ono pa chozungulira, zomwe zimapangitsa kuti pepala la mkuwa likhale lopitirira lomwe pambuyo pake lingakulungidwe pa laminate. Mbali ya ng'oma ya mkuwa idzafanana ndi kuuma kwa ng'oma, pomwe mbali yowonekera idzakhala yolimba kwambiri.

Chojambula cha mkuwa cha PCB chosungidwa ndi electrode

Kupanga mkuwa wosungidwa ndi ma electrode.

Kuti igwiritsidwe ntchito popanga PCB, mbali yosalala ya mkuwa idzayamba yalumikizidwa ku dielectric yagalasi-resin. Mkuwa wotsala wowonekera (mbali ya ng'oma) uyenera kukonzedwa mwadala ndi mankhwala (monga, ndi plasma etching) usanagwiritsidwe ntchito mu njira yokhazikika ya lamination ya mkuwa. Izi zidzaonetsetsa kuti ikhoza kulumikizidwa ku gawo lotsatira mu PCB stackup.

Mkuwa Wosungidwa ndi Ma Electrode Wokonzedwa Pamwamba

Sindikudziwa mawu abwino kwambiri okhudza mitundu yonse yosiyanasiyana ya mankhwala opangidwa pamwambazojambula zamkuwa, motero mutu womwe uli pamwambapa. Zipangizo zamkuwa izi zimadziwika bwino ngati zojambula zosinthidwa, ngakhale pali mitundu ina iwiri yomwe ilipo (onani pansipa).

Ma foil okonzedwanso pogwiritsa ntchito njira yochizira pamwamba yomwe imagwiritsidwa ntchito kumbali yosalala (mbali ya ng'oma) ya pepala la mkuwa lopangidwa ndi electrodeposition. Chigawo chochizira ndi chopyapyala chomwe chimakwirira mkuwa mwadala, kotero chimakhala chomamatira kwambiri ku chinthu chopangidwa ndi dielectric. Mankhwalawa amagwiranso ntchito ngati chotchinga cha okosijeni chomwe chimaletsa dzimbiri. Mkuwa uwu ukagwiritsidwa ntchito popanga mapanelo a laminate, mbali yochizirayo imalumikizidwa ku dielectric, ndipo mbali yotsala yolimba imakhalabe yowonekera. Mbali yowonekera sidzafunika kukwirira kwina kulikonse musanayike; idzakhala kale ndi mphamvu zokwanira kuti igwirizane ndi gawo lotsatira mu PCB stackup.

Mitundu itatu ya zojambulazo zamkuwa zomwe zakonzedwa motsatira njira yosiyana ndi iyi:

Foyilo yamkuwa yotalikira kutentha kwambiri (HTE): Iyi ndi foyilo yamkuwa yokhala ndi electrodeposition yomwe imagwirizana ndi zofunikira za IPC-4562 Giredi 3. Nkhope yowonekera imathandizidwanso ndi chotchinga cha okosijeni kuti isawonongeke panthawi yosungidwa.

Chipepala chokonzedwa kawiri: Mu pepala la mkuwa ili, mankhwalawa amagwiritsidwa ntchito mbali zonse ziwiri za filimuyi. Zinthu zimenezi nthawi zina zimatchedwa pepala lokonzedwa mbali imodzi ndi imodzi.

Mkuwa wotsutsa: Nthawi zambiri suikidwa m'gulu la mkuwa wokonzedwa pamwamba. Foyilo yamkuwa iyi imagwiritsa ntchito utoto wachitsulo pamwamba pa mkuwa wosawoneka bwino, womwe umakokedwa kufika pamlingo womwe ukufunidwa.

Kugwiritsa ntchito pamwamba pa zinthu zamkuwa izi ndikosavuta: zojambulazo zimapindidwa kudzera m'madzi osambira ena a electrolyte omwe amagwiritsa ntchito pulasitala yachiwiri yamkuwa, kutsatiridwa ndi wosanjikiza wa mbewu yotchinga, ndipo pamapeto pake wosanjikiza wa filimu wotsutsana ndi kuipitsidwa.

Zojambula zamkuwa za PCB

Njira zochizira pamwamba pa zojambula zamkuwa. [Chitsime: Pytel, Steven G., et al. "Kusanthula kwa mankhwala amkuwa ndi zotsatira zake pa kufalikira kwa zizindikiro." Mu Msonkhano wa 58 wa Electronic Components and Technology wa 2008, pp. 1144-1149. IEEE, 2008.]

Ndi njira izi, muli ndi zinthu zomwe zingagwiritsidwe ntchito mosavuta mu njira yokhazikika yopangira bolodi yokhala ndi kukonza kochepa.

Mkuwa Wopindidwa ndi Annealed

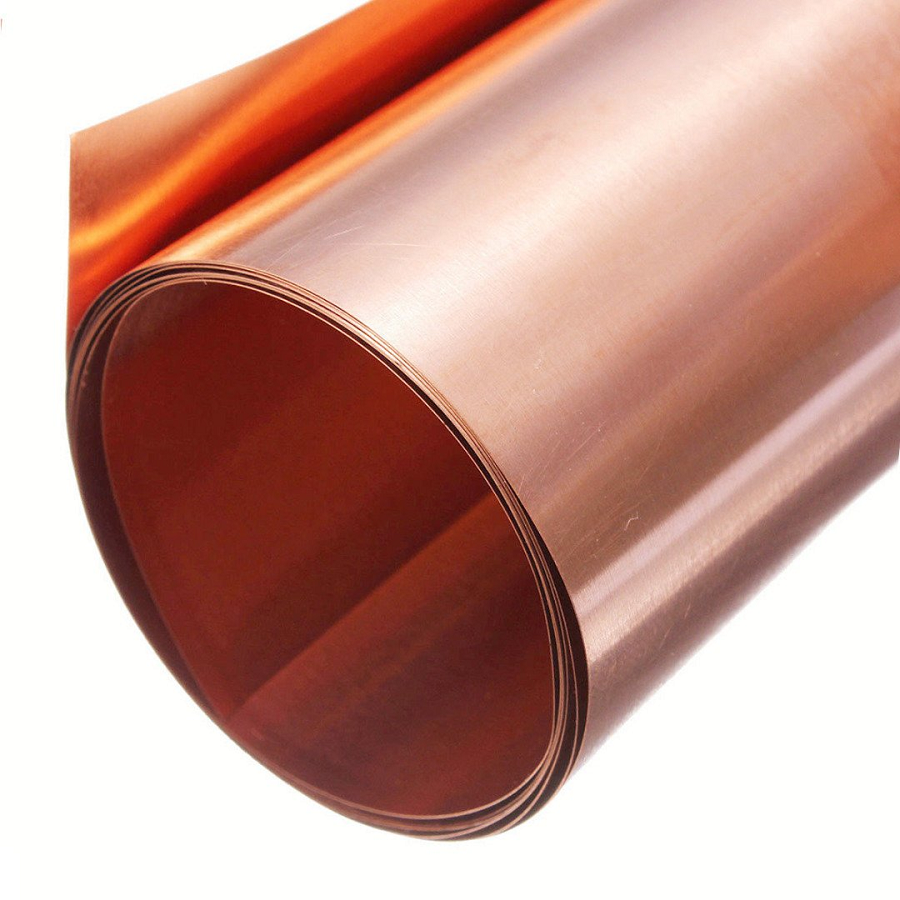

Ma foil a mkuwa opindidwa adzadutsa mpukutu wa foil ya mkuwa kudzera m'ma roller awiri, omwe adzapinda mkuwawo mozizira mpaka makulidwe omwe mukufuna. Kukhwima kwa pepala la foil lomwe likubwera kudzasiyana malinga ndi magawo opindidwa (liwiro, kupanikizika, ndi zina zotero).

Pepala lomwe limatuluka likhoza kukhala losalala kwambiri, ndipo mizere imawonekera pamwamba pa pepala la mkuwa lozunguliridwa. Zithunzi zomwe zili pansipa zikuwonetsa kufananiza pakati pa pepala la mkuwa lopangidwa ndi electrodeposition ndi pepala lozunguliridwa.

Kuyerekeza kwa pepala la mkuwa la PCB

Kuyerekeza kwa ma foil okhala ndi ma electrodeposition ndi ma rolled-annealed.

Mkuwa Wosaoneka Bwino

Sizikutanthauza kuti iyi ndi mtundu wa foil yamkuwa womwe mungapange ndi njira ina. Mkuwa wotsika ndi mkuwa wopangidwa ndi electrode womwe umakonzedwa ndikusinthidwa ndi njira ya micro-roughening kuti upereke roughness yotsika kwambiri yokhala ndi roughening yokwanira yomatirira ku substrate. Njira zopangira foil zamkuwa izi nthawi zambiri zimakhala zaumwini. Foil izi nthawi zambiri zimagawidwa m'magulu a ultra-low profile (ULP), very low profile (VLP), ndi just low-profile (LP, pafupifupi 1 micron average roughness).

Nkhani Zofanana:

N’chifukwa chiyani Copper Foil imagwiritsidwa ntchito popanga PCB?

Chojambula cha Copper Chogwiritsidwa Ntchito mu Bodi Yosindikizidwa ya Circuit

Nthawi yotumizira: Juni-16-2022