Makampani opanga zida za PCB adataya nthawi yayitali ndikupanga zida zomwe zimapereka kutayika kotsika kwambiri kotheka. Pamawonekedwe othamanga kwambiri komanso ma frequency apamwamba, kutayika kumachepetsa mtunda wofalitsa ma siginecha ndikusokoneza ma siginecha, ndipo zipangitsa kupatuka komwe kumawonekera mumiyeso ya TDR. Pamene tikupanga bolodi lililonse losindikizidwa ndikukhazikitsa mabwalo omwe amagwira ntchito pafupipafupi kwambiri, zitha kukhala zokopa kusankha mkuwa wosalala kwambiri pamapangidwe onse omwe mumapanga.

Ngakhale zili zowona kuti kuuma kwa mkuwa kumapangitsa kuti pakhale kusokonekera komanso kutayika, kodi chojambula chanu chamkuwa chiyenera kukhala chosalala bwanji? Kodi pali njira zosavuta zomwe mungagwiritse ntchito kuthana ndi zotayika popanda kusankha mkuwa wosalala kwambiri pamapangidwe aliwonse? Tiona mfundo izi m'nkhaniyi, komanso zimene mungayang'ane ngati mutayamba kugula PCB zipangizo stack.

Mitundu yaZithunzi za PCB Copper

Nthawi zambiri tikamalankhula za mkuwa pazinthu za PCB, sitilankhula za mtundu wina wa mkuwa, timangolankhula za roughness yake. Njira zosiyanasiyana zoyikamo mkuwa zimapanga makanema okhala ndi makulidwe osiyanasiyana, omwe amatha kusiyanitsa bwino ndi chithunzi cha scanning electron microscope (SEM). Ngati mukugwira ntchito pama frequency apamwamba (nthawi zambiri 5 GHz WiFi kapena kupitilira apo) kapena kuthamanga kwambiri, ndiye kuti samalani ndi mtundu wa mkuwa womwe wafotokozedwa patsamba lanu.

Komanso, onetsetsani kuti mwamvetsetsa tanthawuzo la makonda a Dk mu datasheet. Onerani podikasitiyi ndi John Coonrod wochokera ku Rogers kuti mudziwe zambiri za Dk. Poganizira izi, tiyeni tiwone mitundu yosiyanasiyana ya zojambula zamkuwa za PCB.

Electrodeposited

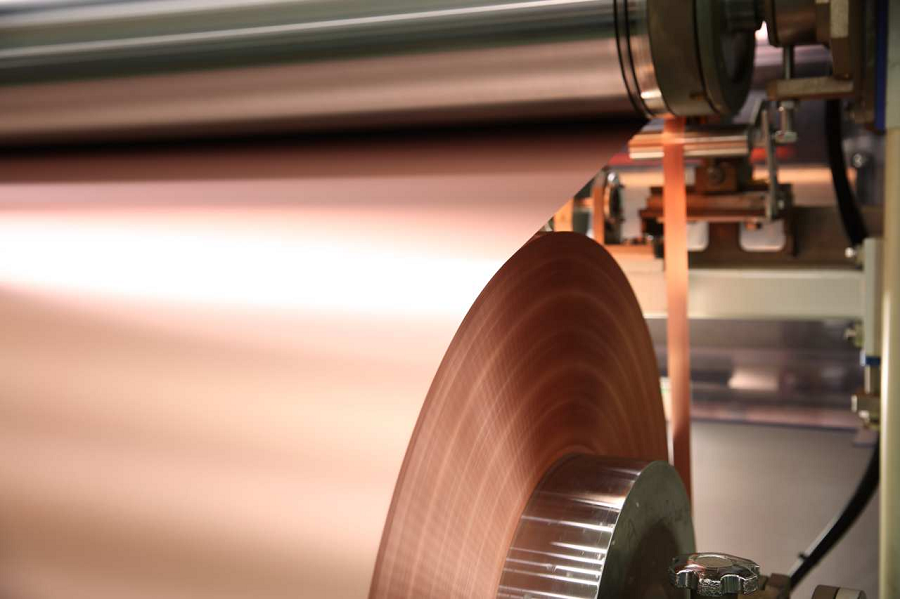

Pochita izi, ng'oma imawomba kudzera mu njira ya electrolytic, ndipo electrodeposition reaction imagwiritsidwa ntchito "kukula" zojambula zamkuwa pa ng'oma. Pamene ng'oma ikuzungulira, filimu yamkuwa yotulukayo imakulungidwa pang'onopang'ono pa chogudubuza, kupereka pepala losalekeza lamkuwa lomwe pambuyo pake likhoza kukulungidwa pa laminate. Mbali ya ng'oma yamkuwa imagwirizana kwambiri ndi makulidwe a ng'oma, pamene mbali yowonekera idzakhala yovuta kwambiri.

Electrodeposited PCB copper zojambulazo

Electrodeposited mkuwa kupanga.

Kuti agwiritsidwe ntchito pakupanga kokhazikika kwa PCB, mbali yoyipa yamkuwayo imayamba kulumikizidwa ndi dielectric yagalasi-resin. Mkuwa wotsalira (m'mbali mwa ng'oma) uyenera kuwuzidwa mwadala ndi mankhwala (mwachitsanzo, ndi plasma etching) usanagwiritsidwe ntchito munjira yoyezera zovala za mkuwa. Izi ziwonetsetsa kuti zitha kulumikizidwa ku gawo lotsatira la PCB stackup.

Mkuwa Wopangidwa ndi Electrodeposited Copper

Sindikudziwa mawu abwino kwambiri omwe amaphatikiza mitundu yonse yamitundu yosiyanasiyana yamankhwalazojambula zamkuwa, motero mutu womwe uli pamwambawu. Zida zamkuwazi zimadziwika bwino kwambiri ngati zojambulazo zosinthidwa, ngakhale kuti mitundu ina iwiri ilipo (onani pansipa).

Zojambula zosinthidwa zosinthidwa zimagwiritsa ntchito mankhwala apamtunda omwe amapaka mbali yosalala (mbali ya ng'oma) ya pepala lamkuwa lopangidwa ndi electrodeposited. Chosanjikiza chamankhwala ndi chopaka chopyapyala chomwe chimawumitsa mwadala mkuwa, motero chimamatira kwambiri kuzinthu za dielectric. Mankhwalawa amagwiranso ntchito ngati chotchinga cha okosijeni chomwe chimalepheretsa dzimbiri. Pamene mkuwa uwu umagwiritsidwa ntchito popanga mapanelo a laminate, mbali yowonongeka imamangiriridwa ku dielectric, ndipo mbali yotsalira yotsalira imakhalabe yowonekera. Mbali yowonekera sidzafunika kuwongoleredwa kwina kulikonse musanawomedwe; idzakhala ndi mphamvu zokwanira kuti zigwirizane ndi gawo lotsatira la PCB stackup.

Zosiyanasiyana zitatu pa zojambula zamkuwa zomwe zimagwiritsidwa ntchito kumbuyo ndizo:

Kutentha kwambiri (HTE) zojambula zamkuwa: Ichi ndi chojambula chamkuwa chokhala ndi electrodeposited chomwe chimagwirizana ndi IPC-4562 Grade 3 specifications. Nkhope yowonekera imathandizidwanso ndi chotchinga cha okosijeni kuti chiteteze dzimbiri panthawi yosungira.

Chojambula chopangidwa kawiri: Pazojambula zamkuwa izi, mankhwalawa amagwiritsidwa ntchito kumbali zonse za filimuyo. Izi nthawi zina zimatchedwa zojambulazo za ng'oma.

Resistive Copper: Izi sizimatchulidwa ngati mkuwa wopangidwa pamwamba. Chojambula chamkuwachi chimagwiritsa ntchito zokutira zachitsulo pamwamba pa matte a mkuwa, zomwe zimawuliridwa mpaka mulingo womwe ukufunidwa.

Kugwiritsa ntchito mankhwala apamwamba pazida zamkuwa ndi zowongoka: zojambulazo zimakulungidwa kudzera mumadzi osambira owonjezera a electrolyte omwe amapaka mkuwa wachiwiri, wotsatiridwa ndi wosanjikiza wambewu yotchinga, ndipo pomaliza pake ndi filimu yotsutsa kuwononga.

Chojambula chamkuwa cha PCB

Njira zochizira pamwamba pazojambula zamkuwa. [Kuchokera: Pytel, Steven G., et al. "Kusanthula kwamankhwala amkuwa ndi zotsatira zake pakufalitsa chizindikiro." Mu 2008 58th Electronic Components and Technology Conference, tsamba 1144-1149. IEE, 2008.]

Ndi njirazi, muli ndi zinthu zomwe zingagwiritsidwe ntchito mosavuta mu ndondomeko yopangira bolodi yokhala ndi zowonjezera zochepa zowonjezera.

Mkuwa Wokulungidwa-Annealed

Zojambula zamkuwa zokulungidwa zimadutsa mpukutu wa zojambulazo za mkuwa kupyola muzodzigudubuza, zomwe zidzazizira pepala la mkuwa mpaka makulidwe omwe mukufuna. Kuuma kwa pepala lopangidwa ndi zojambulazo kumasiyana malinga ndi magawo ogubuduza (liwiro, kuthamanga, etc.).

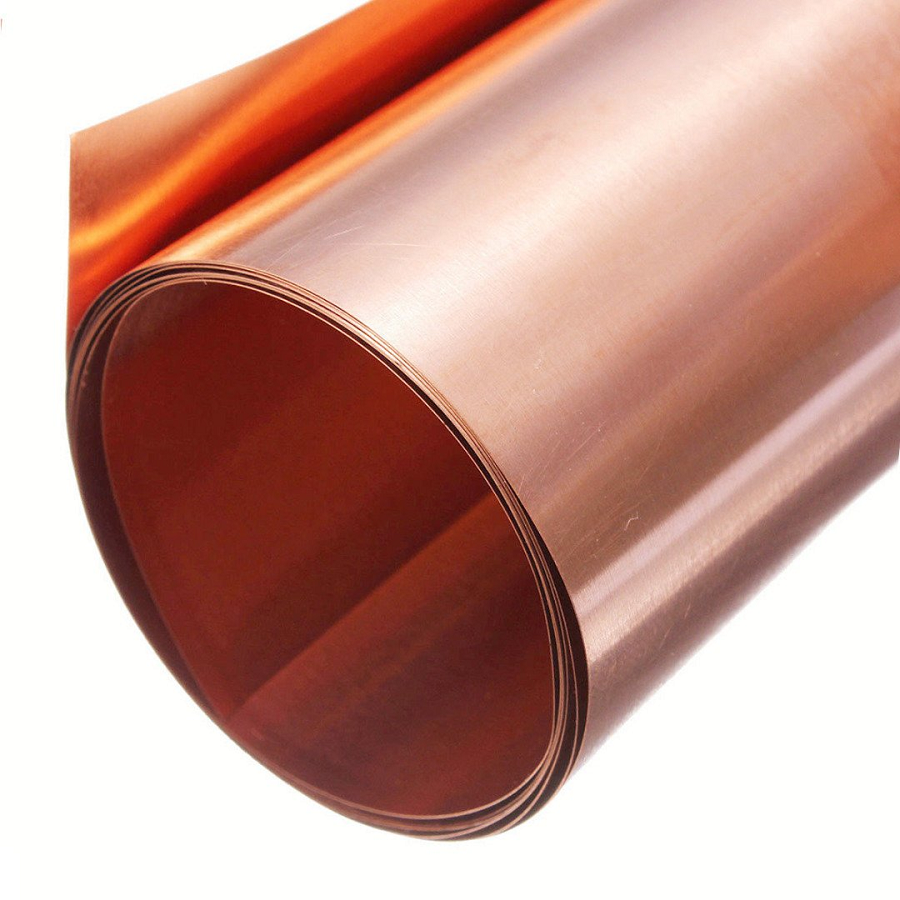

Chotsatiracho chikhoza kukhala chosalala kwambiri, ndipo mizere imawonekera pamwamba pa pepala lamkuwa lopindidwa. Zithunzi zomwe zili pansipa zikuwonetsa kufananitsa pakati pa chojambula chamkuwa chokhala ndi electrodeposited ndi zojambulazo zopindidwa.

Kuyerekeza kwa zojambula zamkuwa za PCB

Kuyerekeza kwa electrodeposited vs.

Mkuwa Wotsika Kwambiri

Izi sizikutanthauza mtundu wa zojambula zamkuwa zomwe mungapange ndi njira ina. Low-mbiri mkuwa ndi electrodeposited mkuwa kuti mankhwala ndi kusinthidwa ndi yaying'ono-roughening ndondomeko kupereka otsika pafupifupi roughness ndi okwanira roughening kwa adhesion ku gawo lapansi. Njira zopangira zojambula zamkuwazi nthawi zambiri zimakhala zaumwini. Zojambulazi nthawi zambiri zimagawidwa ngati ultra-low profile (ULP), very low profile (VLP), komanso zotsika kwambiri (LP, pafupifupi 1 micron average roughness).

Zolemba zogwirizana nazo:

Chifukwa chiyani Copper Foil amagwiritsidwa ntchito pa PCB Manufacturing?

Chojambula Chamkuwa Chogwiritsidwa Ntchito Pagulu Losindikizidwa Lozungulira

Nthawi yotumiza: Jun-16-2022